FLEXIBILITY AT SCALE

Manufacturer of stock and custom carbon fiber sheets, blocks, and components at the quantities you need

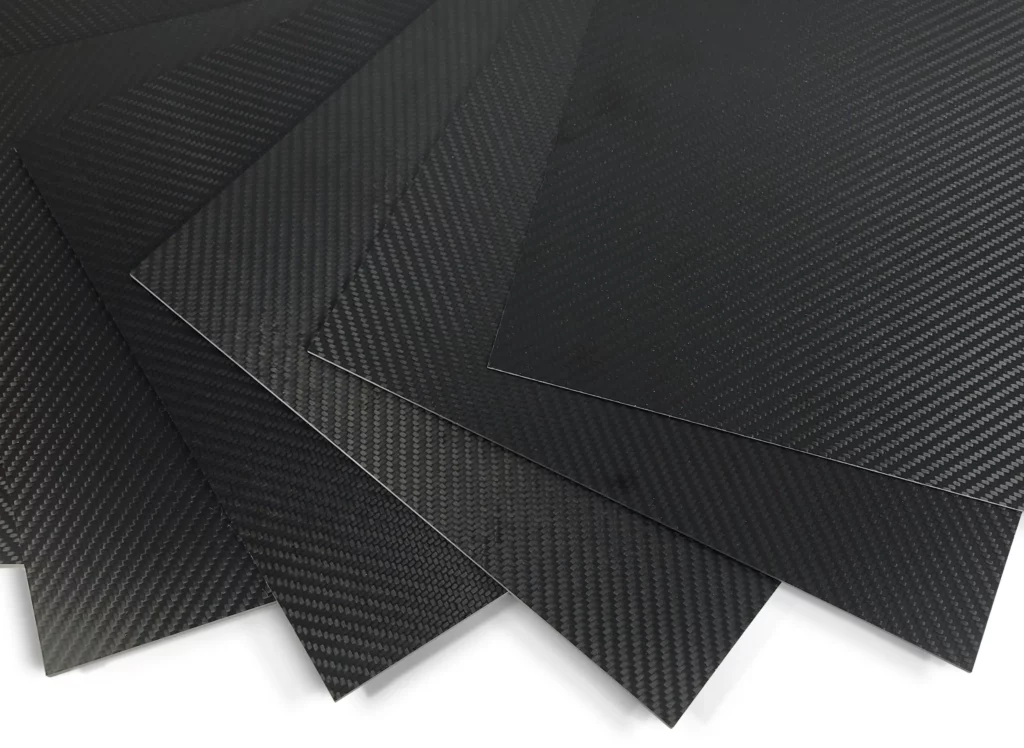

Carbon Fiber Sheets and Plates

Carbon Fiber Parts and Components

Forged Carbon Fiber Blocks

Why Work With Elevated Materials?

At Elevated Materials, we have decades of experience producing carbon fiber sheets, parts, blocks, and other products at scale. We are extremely flexible, and can efficiently handle both small and large volumes, as well as custom layups.

Our carbon fiber sheets and parts are press cured rather than resin infused, meaning Elevated Materials provides better consolidation, more uniformity, and easier machining. With our relentless dedication to customer service and our flexible array of customization options, we can work with you to create exactly what you need, when you need it-every time.

What We Do

Carbon Fiber Sheets and Plates

We manufacture high-quality, flat carbon fiber sheets and carbon fiber plates that can be used in a huge array of industries and applications. Our carbon fiber sheets are press cured to provide better consolidation, more uniformity, greater consistency, and a better surface finish. We provide carbon fiber sheets in custom thicknesses and sizes, and can create custom layups to meet specific performance requirements.

Carbon Fiber Parts and Components

Elevated Materials is one of the only vertically integrated carbon fiber part manufacturers in the country! We make our own press cured carbon fiber sheets and blocks to ensure quality of material, easy machining, and minimal supply chain issues. We are experts at helping customers navigate the transition from parts made of traditional materials to carbon fiber parts, and can provide full service manufacturing engineering for every stage of the journey, from prototyping to high-volume production.

Carbon Fiber Blocks and Billets

Our carbon fiber blocks and billets boast a lower density and a higher strength-to-weight ratio than traditional materials, making them the superior choice for products that face frequent wear-and-tear or where weight is at a premium. Elevated Materials both manufactures and machines forged carbon fiber blocks up to 4.5" thick.

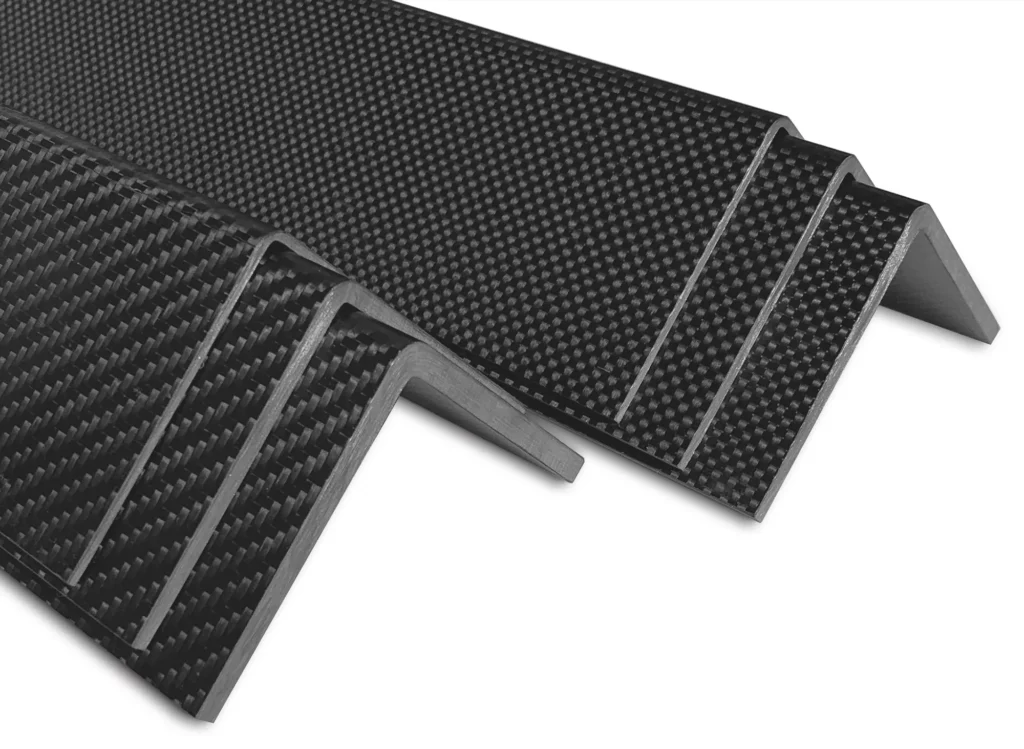

Carbon Fiber Angles

Our carbon fiber angles are press-molded using a 0/90 layup schedule, creating a balance of fiber directions that optimizes both cost and mechanical properties. Our angles yield an extremely low void fraction and a smooth finish on both sides, and are ideally suited for a variety of applications. Elevated Materials both manufactures and machines our carbon fiber angles, so we can supply stock angles or finished angles with custom drilling and cutting.

What Our Clients Say

Learn More On Our Blog

Elevating Manufacturing Flexibility: Rapid Prototyping to Large-Scale Production

In the manufacturing space, agility and adaptability are paramount. Companies need to be able to pivot from rapid prototyping to large-scale production seamlessly, meeting the demands of a dynamic market. Elevated Materials excels in this arena, offering unmatched manufacturing flexibility that sets it apart from the competition. Rapid Prototyping Excellence At Elevated Materials, we understand…

A Look into CNC Machining Carbon Fiber Billet at Elevated Materials

Understanding Amorphous Carbon Fiber Billets Amorphous carbon fiber billets are at the forefront of material technology, offering a blend of strength, lightweight, and durability that traditional materials can scarcely match. Unlike laminate counterparts, amorphous carbon fibers do not have a regular layered structure, which contributes to their more uniform mechanical properties. This makes them ideal…

Accelerating Your Project with Rapid Quote Turnaround Times

In the dynamic world of manufacturing, time is often the most precious resource. For companies working with manufacturers, the time to receive a quote for a project can be a game-changer. Rapid quote turnaround times not only streamline the initial stages of a project but also set the tone for efficient production and delivery. Here,…

A Few of Our Satisfied Customers