Advantages of Forged Carbon Fiber Blocks and Billets

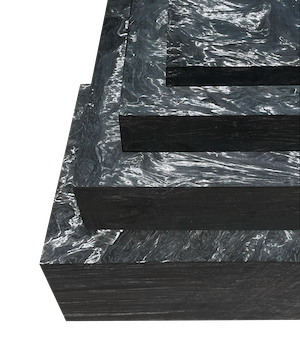

In the fast-paced world of advanced materials, forged carbon fiber blocks (also known as forged carbon fiber billets) have emerged as an innovative material option for manufacturing 3D parts and components. These blocks offer a combination of mechanical properties and machinability that make them an attractive option for part manufacturing across multiple industries.

Advantages of forged carbon fiber blocks and billets

1. Low Density and Light Weight Resulting in Higher-Performing Parts:

The hallmark of forged carbon fiber blocks lies in their incredibly low density. This lightweight attribute has the potential to revolutionize industries like aerospace and automotive, where weight reduction translates to improved efficiency and enhanced performance of parts that other materials may struggle to match.

2. High Strength-to-Weight Ratio:

When it comes to strength and weight, conventional materials often find themselves in a trade-off scenario. However, parts made of forged carbon fiber blocks don’t need to compromise with their exceptional strength-to-weight ratio. This unique combination empowers engineers and designers to create robust structures that can withstand rigorous demands.

3. Higher Stiffness:

The mechanical properties of materials often dictate their usability in critical applications. Parts made from forged carbon fiber blocks excel in stiffness, providing a structural advantage that can be leveraged in designs requiring rigidity, precision, and stability. The ability to maintain form under varying stressors enhances the reliability of components and ensures consistent performance over time.

4. Lower Coefficient of Thermal Expansion:

In a world where temperature variations are the norm, materials that can adapt without compromising integrity are invaluable. Parts manufactured from forged carbon fiber blocks present a lower coefficient of thermal expansion compared to traditional materials. This quality equips them to thrive in environments with fluctuating temperatures, maintaining their dimensional integrity.

5. Diverse Applications:

Forged carbon fiber blocks have demonstrated their adaptability across a wide array of industries, making a significant impact in various applications. From laser alignment to optics, metrology, automotive manufacturing, industrial robotics, and aerospace, these blocks have showcased their versatility. The product excels in sectors requiring precision, lightweight durability, and structural integrity. As a material of choice in such a diverse range of industries, carbon fiber blocks can meet the unique demands of each field.

Why choose Elevated Materials’s forged carbon fiber blocks and billets?

- Versatile Thickness: Elevated Material crafts blocks up to 4 ½ inches thick (12.5 x 12.5 x 4.5), enabling intricate designs and diverse applications. Blocks can be provided to whatever cut dimensions are required.

- Superior Machinability: Elevated Materials’s carbon fiber blocks are manufactured for machinability. Carbon fiber blocks from Elevated Materials are incredibly consistent, making it easier to machine and produce higher-quality parts.

- Domestic Production: Proudly made in the USA, Elevated Materials’s offerings are quality-assured and support local industries.

- Comprehensive Machining Services: Our vertically integrated approach includes machining services, streamlining manufacturing, and ensuring seamless design-to-execution compatibility.

- Innovative Development: In an industry where very few suppliers manufacture their own products, our expertise and innovation allow us to develop and produce forged carbon fiber blocks in-house.

- Sustainable Approach: By incorporating upcycled and recycled materials, Elevated Material contributes to sustainability and a circular economy.

Want to learn more?

The team at Elevated Materials would love to work with you to transition to carbon fiber blocks and billets. Contact us today to get started!