Knowledge Base

Your source for best practices and tips for working with carbon fiber.

In the manufacturing space, agility and adaptability are paramount. Companies need to be able to pivot from rapid prototyping to large-scale production seamlessly, meeting the demands of a dynamic market. Elevated Materials excels in this arena, offering unmatched manufacturing flexibility that sets it apart from the competition.Rapid Prototyping ExcellenceAt Elevated Materials, we understand that speed…

Understanding Amorphous Carbon Fiber Billets Amorphous carbon fiber billets are at the forefront of material technology, offering a blend of strength, lightweight, and durability that traditional materials can scarcely match. Unlike laminate counterparts, amorphous carbon fibers do not have a regular layered structure, which contributes to their more uniform mechanical properties. This makes them ideal…

In the dynamic world of manufacturing, time is often the most precious resource. For companies working with manufacturers, the time to receive a quote for a project can be a game-changer. Rapid quote turnaround times not only streamline the initial stages of a project but also set the tone for efficient production and delivery. Here,…

Please Join Us At CAMX in Atlanta in Join the Elevated Materials team at CAMX – the Composites and Advanced Materials Expo – the largest, most comprehensive composites and advanced materials event in North America. Visit us at booth T49 at CAMX in Atlanta. You can’t miss us. Questions? Contact Us. We are here to…

In the fast-paced world of advanced materials, forged carbon fiber blocks (also known as forged carbon fiber billets) have emerged as an innovative material option for manufacturing 3D parts and components. These blocks offer a combination of mechanical properties and machinability that make them an attractive option for part manufacturing across multiple industries. Advantages of…

What does Elevated Materials do? In addition to our carbon fiber sheet and billet manufacturing, we offer a wide range of machining and finishing services to deliver finished parts that can be used in a wide range of applications. All of these processes take place in-house giving us a lot of flexibility and allows us…

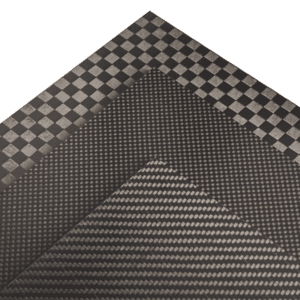

There are so many options for manufacturing the surface finish on a carbon fiber panel. The surface finish you choose can make a difference in panel cost, and panel performance. The purpose of this is to explain the different surface finishes available from Elevated Materials, and when to use them. Matte Finish This is a…

For use as brackets or components, carbon fiber has several properties that give it an advantage over other materials. Carbon is lightweight corrosion resistant and stiff. Blocks can easily be tapped and milled to any geometry required. Different carbon fiber blocks can have different appearances. Each style has properties that give a unique benefit. Forged…

Elevated Materials is launching a made-to-order program for carbon fiber connectors for T slot and 80/20 aluminum framing extrusions. T slot (or T track or 80/20) aluminum framing is very popular for it’s versatility. Many people consider it to be the modern equivalent of an erector set for adults, you can get all different sizes and lengths…

If you have ever wondered why one piece of carbon fiber might look different from another piece of carbon fiber, you’re not alone. Carbon fiber comes in many different weaves and each one serves a different purpose, and it isn’t just cosmetic. Carbon fibers are made from precursors such as polyacrylonitrile (PAN) and rayon. The…