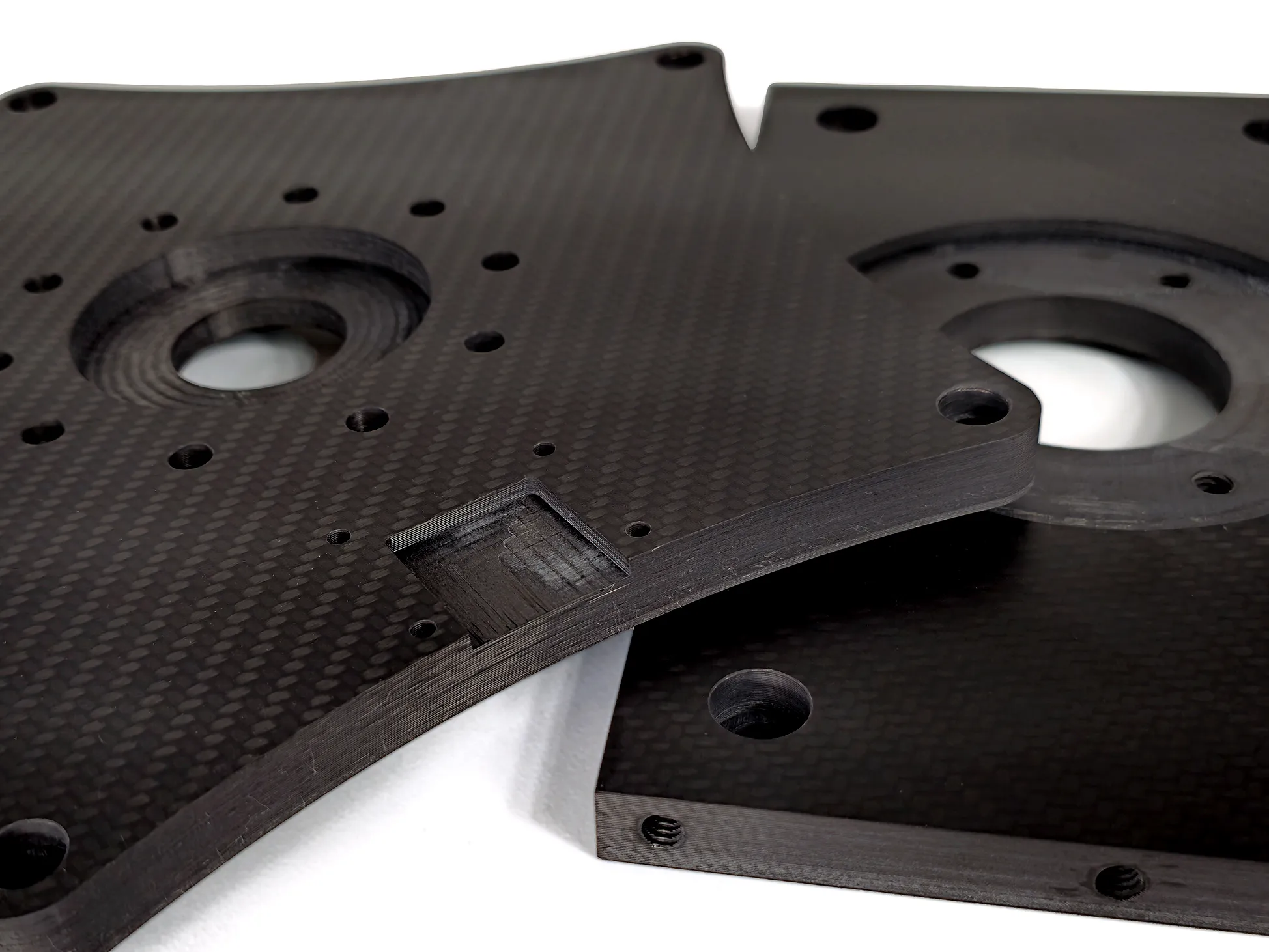

Carbon Fiber Parts and Components

Advantages of Elevated Materials's Carbon Fiber Parts

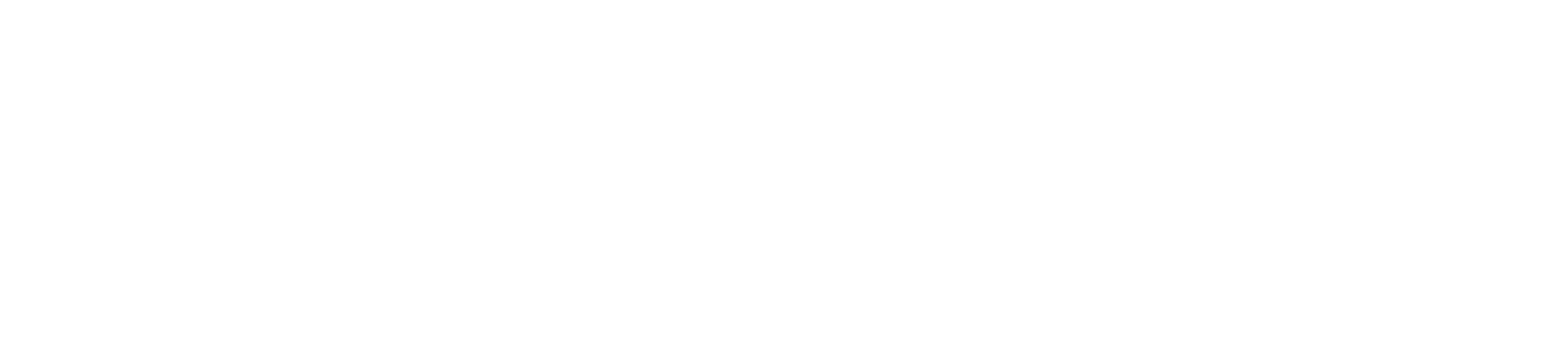

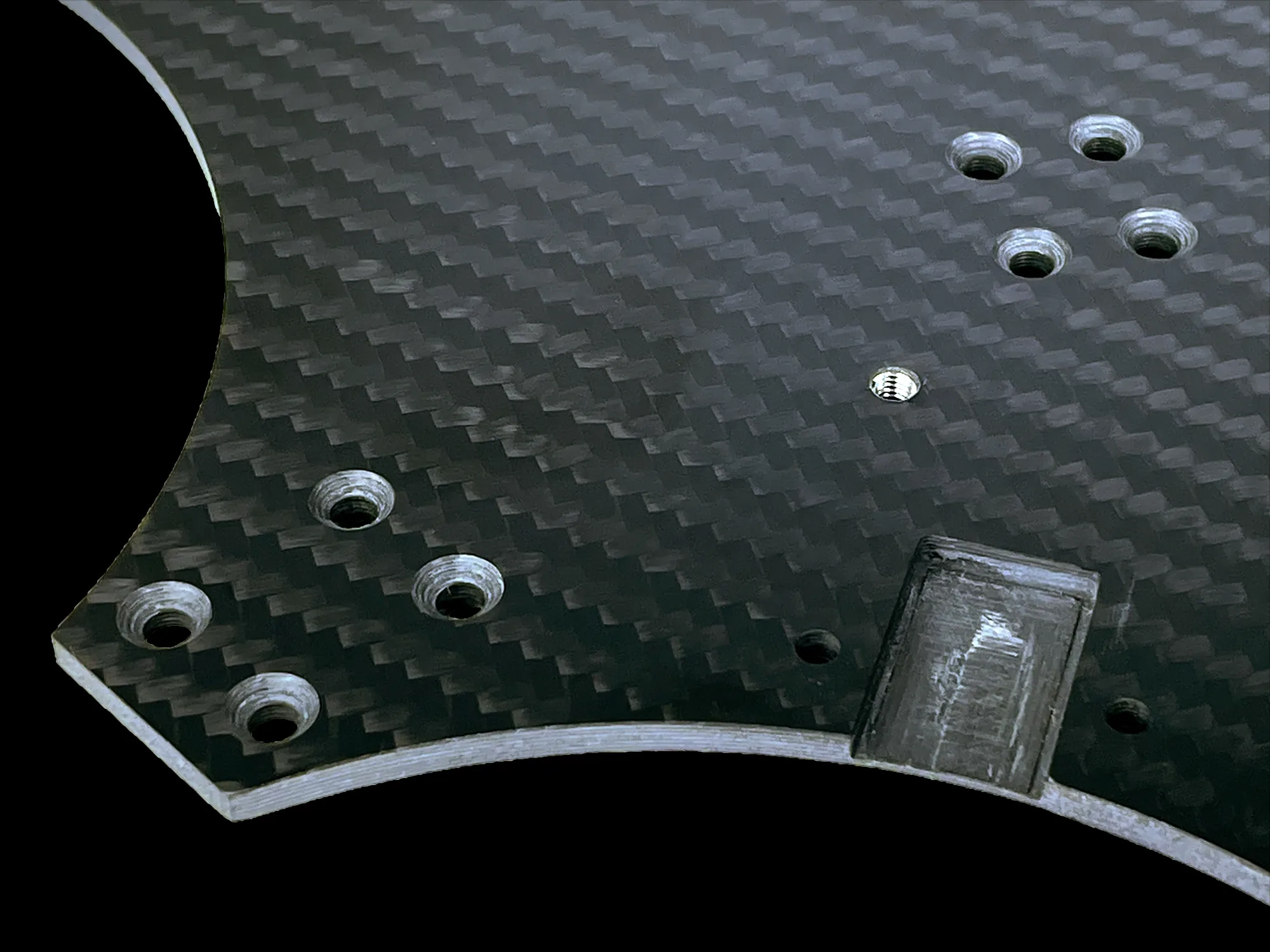

Made from the Highest Quality Carbon Fiber

Our parts are made from carbon fiber sheets and blocks that we manufacture in-house. We specifically design our carbon fiber parts to provide an outstanding and consistent finish that fulfills or exceeds your specific performance requirements.

Production Volume Flexibility

We have decades of experience with carbon fiber part manufacturing, and are flexible enough to fill both large and small orders. We can take your vision from prototyping to high-volume production.

Extensive Carbon Fiber Expertise

Carbon fiber manufacturing is a different beast than traditional materials, and you need a supplier that understands the unique challenges and nuances of the process. At Elevated Materials, we have extensive expertise creating carbon fiber part solutions for clients across a wide range of industries.

Made in the USA

All of our carbon fiber parts are manufactured in the United States by Elevated Materials. By choosing to keep our manufacturing in-house, we minimize supply chain issues and can fulfill your order reliably on time-every time.

Customization Options for Elevated Materials's Custom Carbon Fiber Parts

-

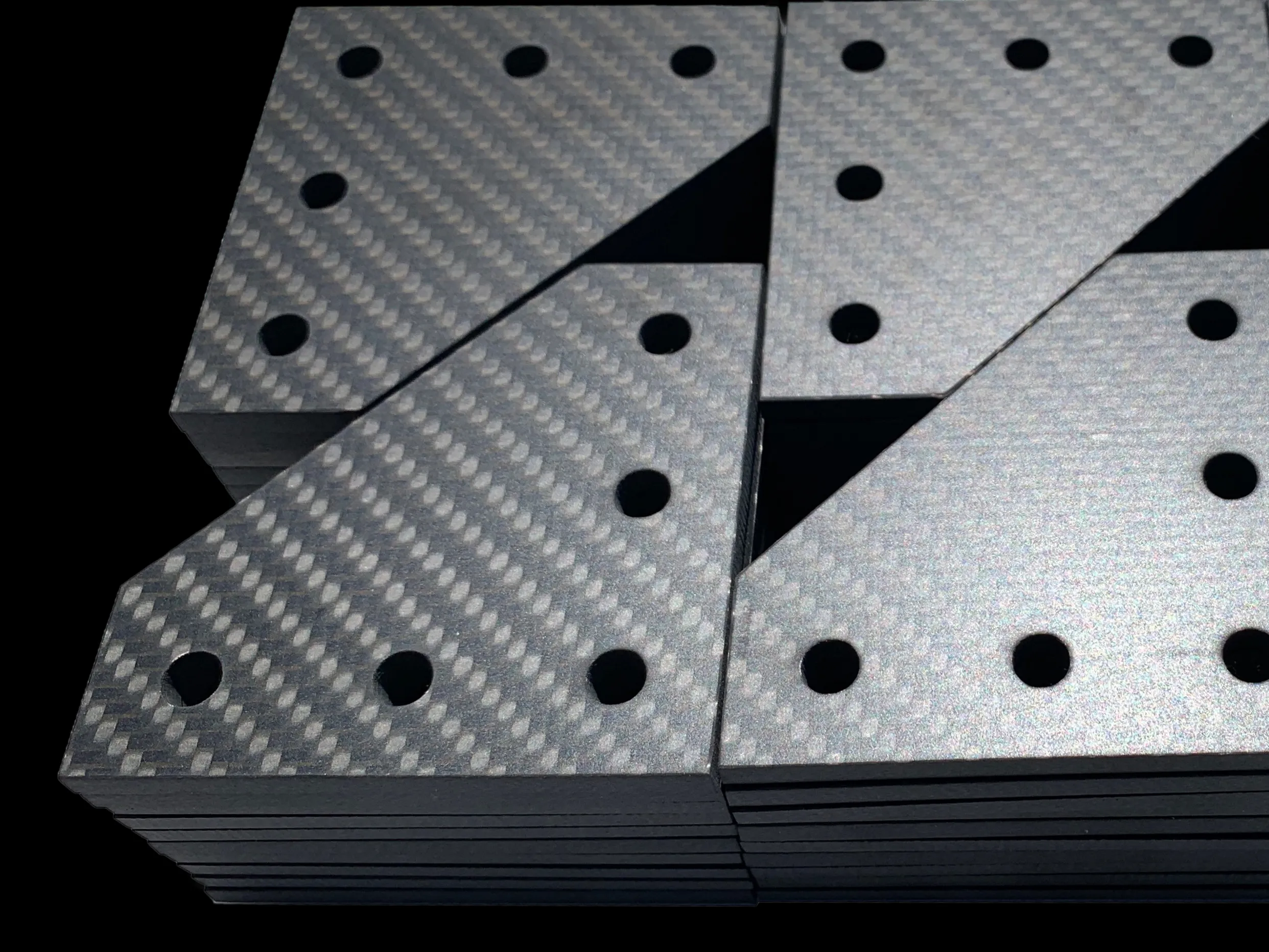

Complex Three-Dimensional Features

-

Simultaneous 5 Axis Milling

-

Robotic Machine Tending

- Chamfers and Fillets

- Countersinks

- 3D Contours

- Threads and Inserts

- Waterjet

- CNC Router

- Plain Weave

- Twill Weave

- Uni-Directional Weave

- Any other weave with customer-provided prepreg material

- Gloss

- Matte

- Peel Ply/Bond Prep Finish

- Non-Traceable

- Traceable

- Parts from 1/4" (6mm) to 66" (1,675mm) long

- Parts from 1/4" (6mm) to 29.5" (750mm) wide

- Parts from 1/64" (.4mm) to 4.5" (115mm) thick

Why Parts Machined from Press Cured Carbon Fiber Stock Have Superior Performance Characteristics and Finish

Parts machined from press cured carbon fiber stock offer more consistent machining compared to resin infused carbon fiber stock, due to their consistent and controlled material properties. Carbon fiber layers are subjected to heat and pressure during press curing, resulting in uniform distribution and fiber alignment, minimal variations in density, and a reduced likelihood of voids or defects.

What Our Clients Say

Lead Engineer

Chief Design Officer

Co-Founder

Contact Us Today to Get Started

(323) 391-1058

info@elevatedmaterials.com

1313 W. 135th St.

Gardena, CA 90247

Submit an RFQ for

Carbon Fiber Parts

A Few of Our Satisfied Customers