Why Use Carbon Fiber?

Lightweight

Carbon fiber is 5 times lighter than steel (ASTM-A1008) and almost 2 times lighter than aluminum when comparing similar sized pieces.

High Strength & Stiffness

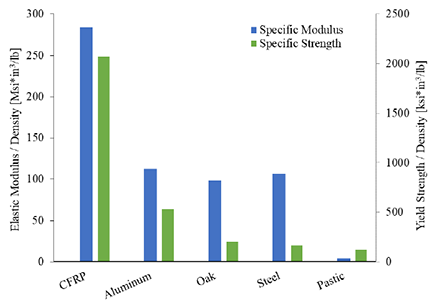

Carbon fiber reinforced polymer (CFRP) has the highest specific strength and modulus (stiffness) per density compared to metal, plastic and wood. (Fig. 1)

Resistance to Corrosion & Chemicals

The epoxy resin is inert and not susceptible to corrosion or rust, and the carbon bonds in the fibers are extremely strong and resistant to oxidization.

Low Thermal Expansion

When metal is exposed to heat, it will expand and weaken which can cause issues and possible failure of the part. Carbon fiber has low thermal expansion.

Low Thermal Conductivity

Metal acts as a conductor, aluminum more than steel, which can transmit or radiate heat to its surroundings and cause heat soak. Carbon fiber has low thermal conductivity.

RF Shielding

Carbon Fiber works well to attenuate, or block radio frequency waves, protecting your devices from scanners or people trying to access your data.

Fig. 1. Comparison of specific strength and modulus values for CFRP, metal, wood and plastic.

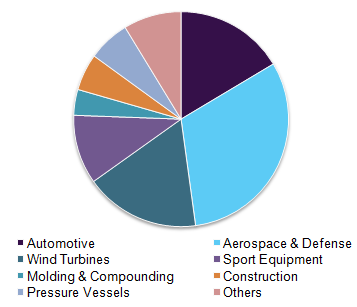

Fig. 2. Global carbon fiber market share by volume demand for different industries, 2016 (%)

Our "Space Grade" Carbon Fiber Material

Rockets and space craft experience extreme loads and forces when launched into space. In order to survive this they must be constructed with strong and durable materials. Another important factor for rockets is weight, that is why carbon fiber is the go-to material for the space industry.

All of our products are made with the same carbon fiber material used in the commercial space flight industry. That is why we say our material is "Space Grade," it has literally been designed for space travel.

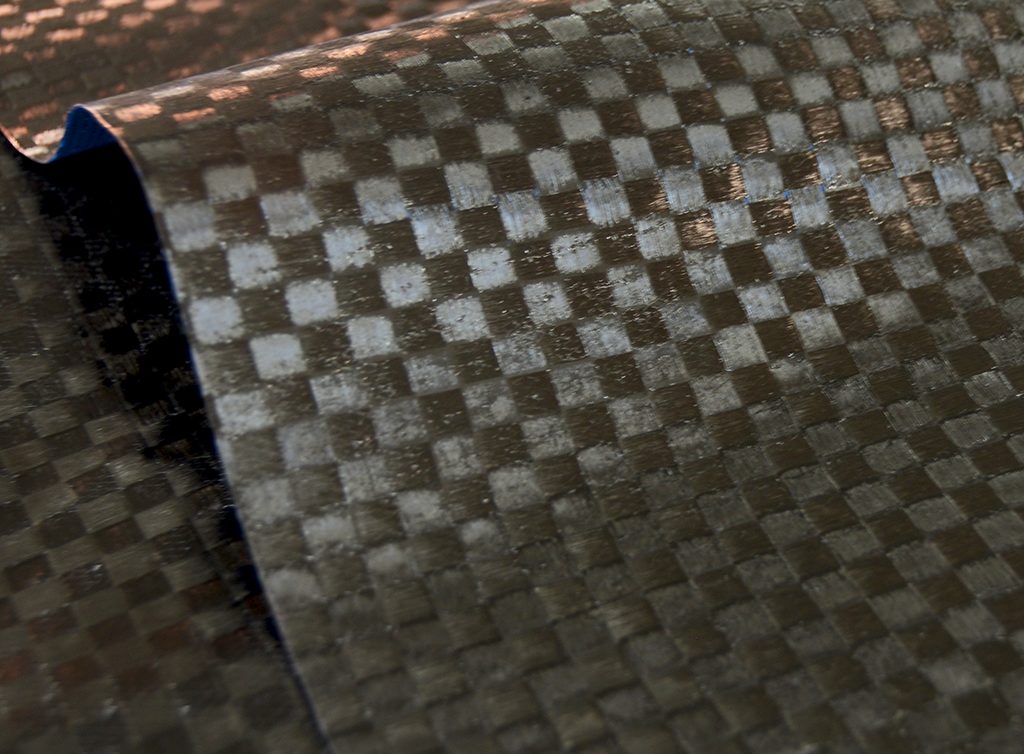

The carbon fiber material we use is resin impregnated woven cloth that is commonly referred to as "pre-preg." It is made with high quality carbon fibers combined with space industry defined resin systems, which separates our material from the rest. Many companies will cut cost with lower quality fibers or inferior resin systems that aren't as durable.

We use heated compression molding to cure the pre-preg material into flat sheets, which we sell on our site. We offer a wide selection of flat sheet with many choices for size and thickness; custom sizes and cuts are also available. We also offer services to support end-to-end part manufacturing, from product design through fulfillment. Click the links below to learn more.

Services Provided

Common Carbon Fiber Applications

We see carbon fiber expanding into many different industries and products, especially as it becomes more affordable. Below we have listed some application segments where we see carbon fiber as having great potential. We want to help bring carbon fiber to new industries, markets and products by making it more available and affordable, while also doing something good for the environment.

Drones - Carbon fiber is great for the chassis parts and rotor arms whether for racing, recreational or industrial drones.

Watersports - Can be used for a wide range of applications from dive fins to kayak accessories and boat instrument panels and trim.

Robotics - Carbon fiber is thin, light and strong, which is perfect for robotic parts large and small, whether structural or not. It can also work well for covers or enclosures.

Transportation - Whether you want to save weight or add some style to your car, truck, ATV, motorcycle or scooter, carbon fiber can serve many different purposes.

Musical Instruments - Carbon fiber has unique tonal qualities and can be used for drum shells or face plates on a Cajon. Or it can add a high tech look, like a pick guard other accents or trim.

Office - Carbon fiber looks great as a desk top or a conference table. It can also be used for shelving, storage or desk dividers. Our glossy finish makes for a unique dry-erase board.